Warehouses have started to incorporate sensors into their infrastructure in order to help control and manage HVAC and lighting systems. Applying smart warehouse energy management to these systems allows for facilities to optimize energy consumption. The lighting in a typical warehouse can account for up to 70% of the facility’s energy use. Meanwhile, smart lighting automatically dims or brightens an area based on activity. HVAC systems have also benefited from these sensors since they can monitor and regulate temperature and ventilation, ensuring product integrity.

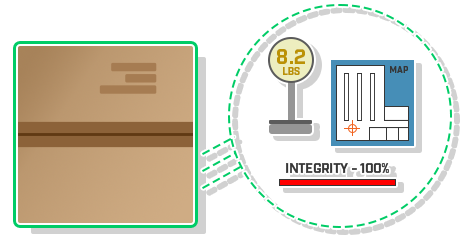

Incorporating IoT into warehousing operations has led to product visibility and security during transportation. Scanners, tags, and cameras are reducing the need for manual tracking of incoming shipments. Scanners can capture data about a shipment’s volume and dimensions. Multi-sensor tags are placed on items and transmit location and condition data to the management system. Because they track real-time visibility, these tags ensure that misplaced items can be located quickly. As a means of damage detection, cameras are also installed near inboard delivery gateways in order to scan shipments for imperfections.

When items are outbound, they are scanned through the outbound gateway in order to ensure order accuracy. These scanners assist in guaranteeing that the correct items are shipped in the correct order. When outbound deliveries are scanned, stock levels are automatically updated in the warehouse’s management system creating an accurate inventory control.

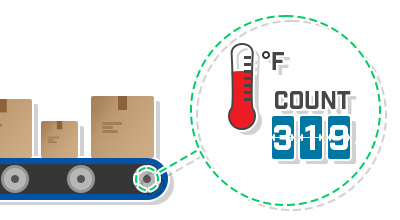

Along with monitoring products in real time, IoT has also led to optimal asset utilization which monitors the use of machinery, equipment, and vehicles in real time. This allows for management to see what and when equipment is in use or idle. Sensors and cameras can be placed on sorting machines, such as conveyer belts, in order to identify the physical stress of the machine by measuring temperature and throughput.

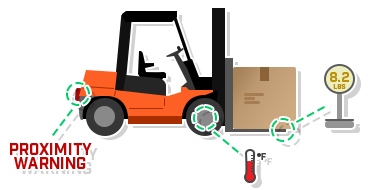

Deploying a mix of sensors and cameras in warehouse settings has improved the health and safety of the workers. Installing both sensors and cameras onto transportation equipment, such a forklift, allows for the operator to carefully maneuver around obstacles and people. Additionally, these sensors can detect when a load is heavy and may not have been safely picked up by the machinery.

The connected workforce has led to new opportunities that monitor the health and safety of both employees and equipment, all while improving the efficiency of internal operations. By installing sensors and cameras throughout these facilities, there has been a reduction in energy consumption, an improvement in product integrity, and a decrease in worker fatigue. Adding smart technology to a warehouse’s operation has made workers' jobs easier and safer.